TUBALL™

graphene nanotubes: advancing

OCSiAl is the global leader in single wall carbon nanotube technologies and the key supplier of nanotube solutions. Explore more than 40 nanotube products for various polymers and electrochemical power sources.

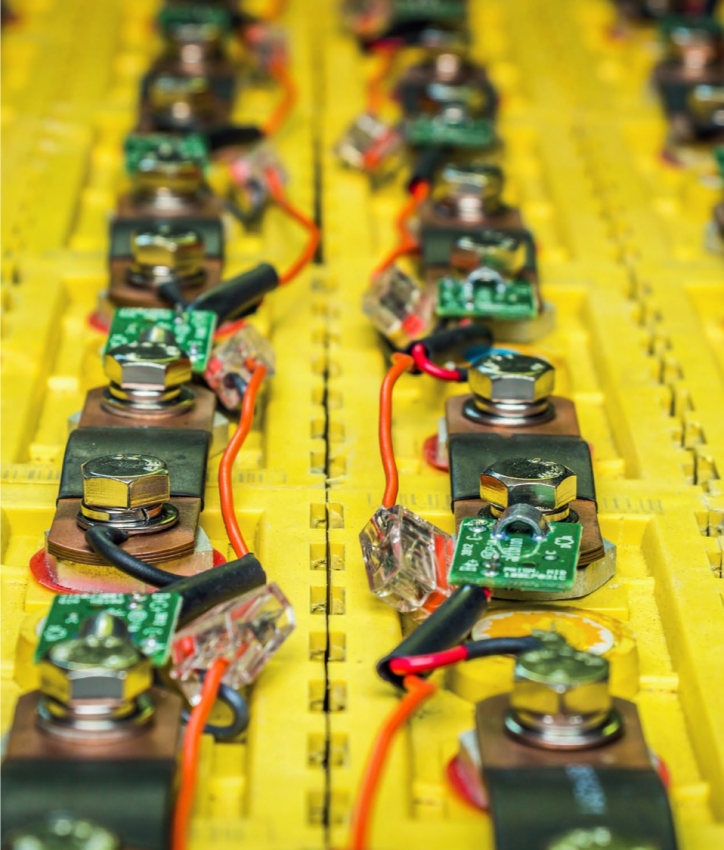

BatteriesHigh-performing conductive and reinforcing additive for battery electrodesLearn moreAEROSPACESmart materials and technologies empowered by nanotubesLearn moreOIL & GASGraphene nanotubes guarantee safety and productivityLearn moreFUTURE OF MOBILITYNanoaugmented transport – intelligent, functional and energy efficientLearn more

Application Cases for

TUBALL™ for SMC COMPOSITES

Versatile conductive additive based on a plasticizer with a stabilizing agent for polyester and vinyl-ester coatings, for melamine and acrylic solvent-based applications

View Product

TUBALL™ for SMC COMPOSITES

PRODUCT

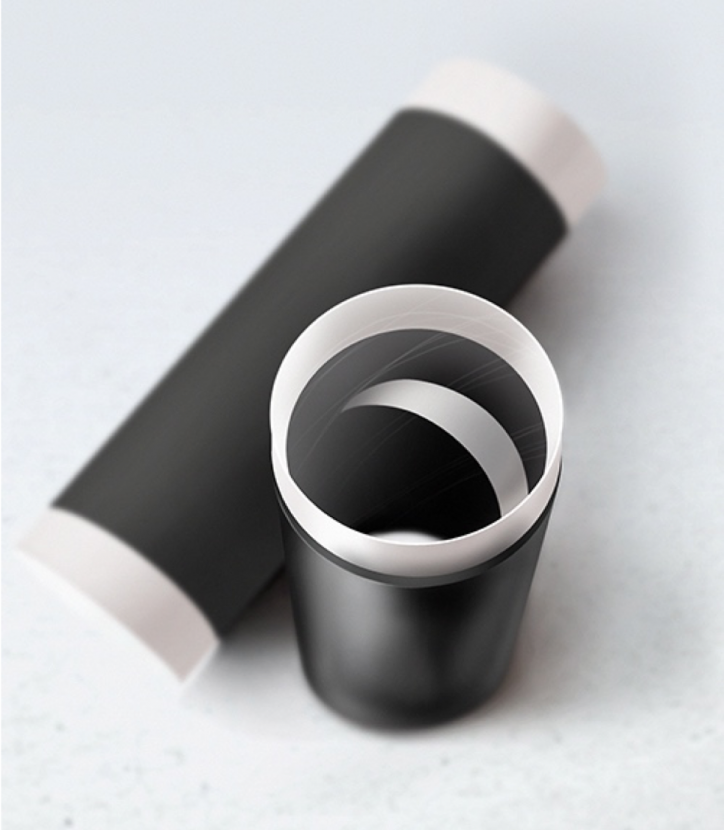

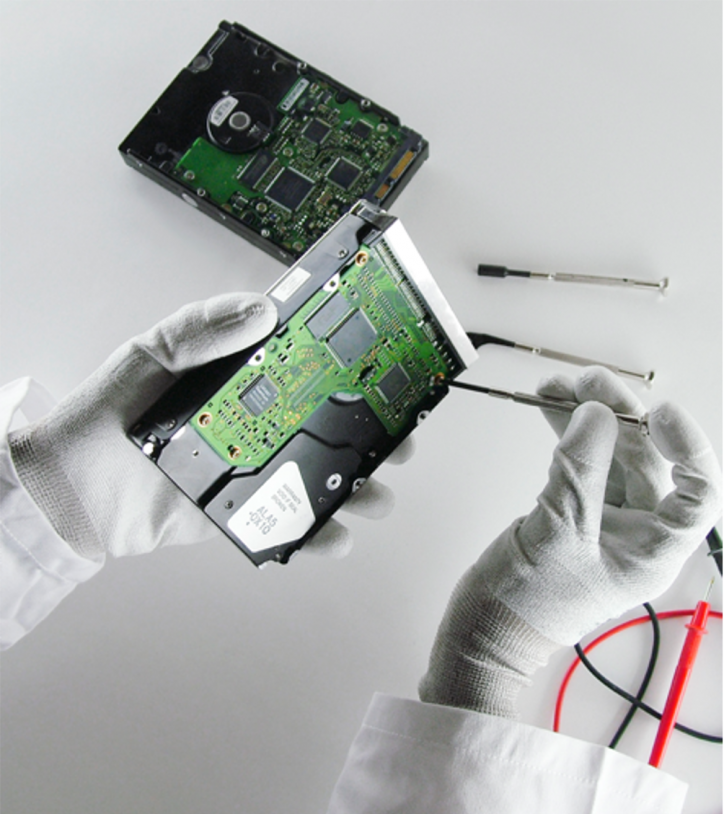

Anti-static SMC composites for using in electronic equipment

REQUIREMENTS

- Volume resistivity of 106–109 Ω∙cm

- Permanent and stable level of resistivity

TUBALL™ SOLUTION

6 wt.% of conductive carbon black as a conductive additive was replaced with

0.2 wt.% of TUBALL™ MATRIX 204

KEY BENEFITS

- Permanent and stable anti-static properties without “hot spots”

- Resistivity is independent of humidity

- Wide range of colors is available

- Clean manufacturing process without carbon black powder or dust

- Original flame retardancy is maintained

Product News

April 17

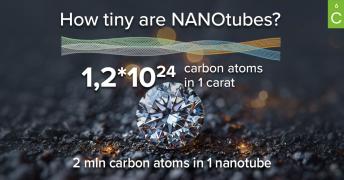

Do we truly know what NANO is? 🧐 Graphene nanotubes are incredibly tiny. Each graphene nanotube comprises ONLY 2 million carbon atoms. To put that in perspective, a one-carat diamond contains about 1,200,000,000,000,000,000,000,000 (1.2×10^24) carbon atoms.

Learn more on graphene nanotubes: https://tuball.com/about-tuball?utm_source=Facebook&utm_medium=TUBALL+figures+&utm_campaign=April+17%2724

#nanotubes #nano #carbon

Read on Facebook

April 16

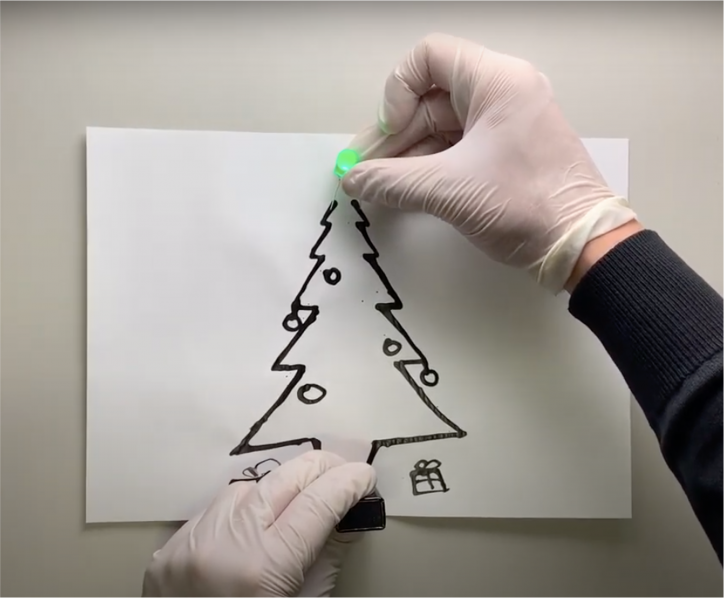

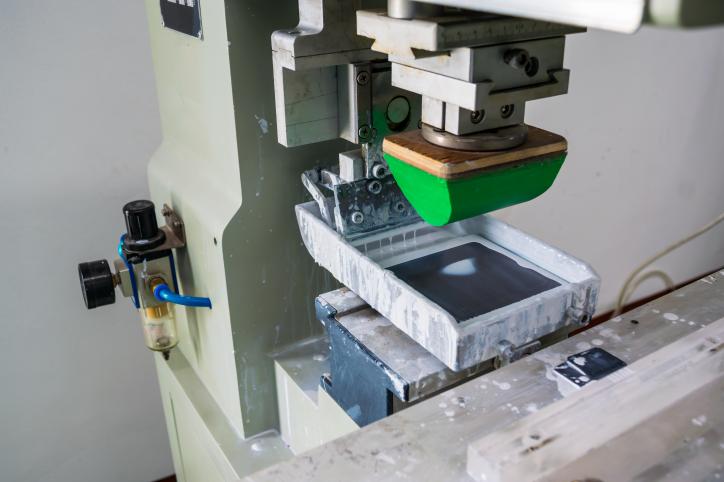

[#video] Compliance with safety regulations and ATEX zone requirements have driven BÜFA Composite Systems to upgrade their high-performance gelcoats with graphene nanotubes. A wider color selection for conductive solutions, batch-to-batch reliability, no compromise in application, good weathering and chemical resistance performance, no contamination, and other additional benefits of innovative conductive gelcoats were unveiled in a joint presentation with OCSiAl at JEC Composites: https://youtu.be/kT8Dq50ktQM

Learn more on graphene nanotubes for composites: https://tuball.com/nanotubes-for/conductive-composites?utm_source=Facebook&utm_medium=JEC%272024+presentation

#composites #gelcoats #ATEX #applicationcase

Read on FacebookHead office

1 Rue de la Poudrerie,

L-3364, Leudelange,

Grand-Duché de Luxembourg