TUBALL™

graphene nanotubes: advancing

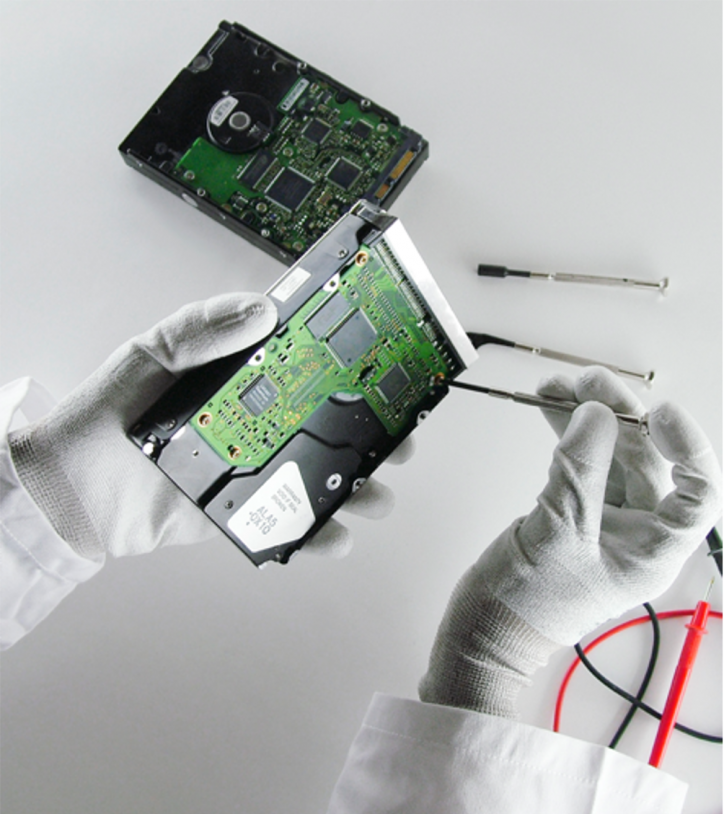

OCSiAl is the global leader in single wall carbon nanotube technologies and the key supplier of nanotube solutions. Explore more than 40 nanotube products for various polymers and electrochemical power sources.

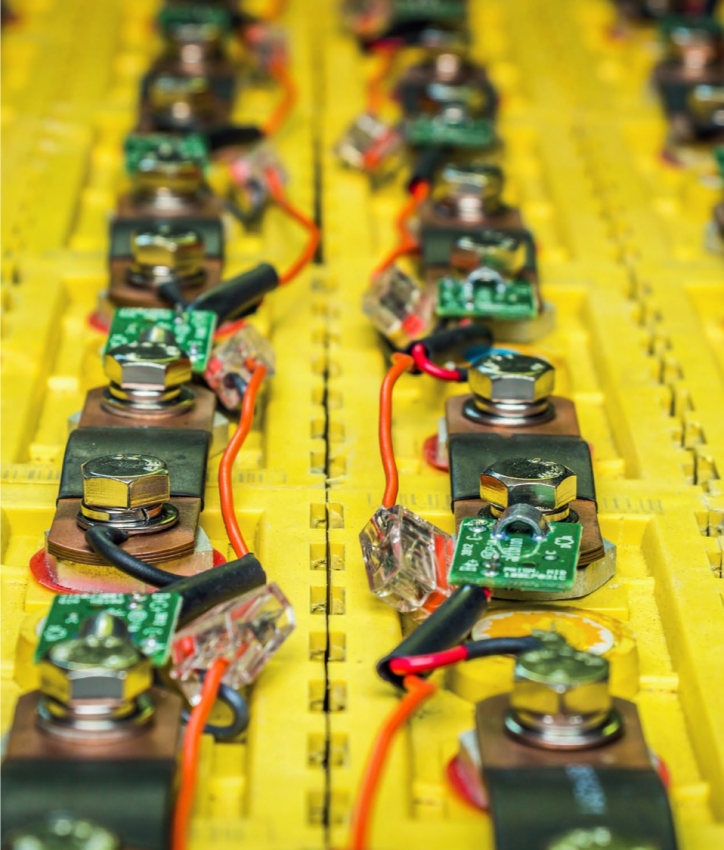

BatteriesHigh-performing conductive and reinforcing additive for battery electrodesLearn moreAEROSPACESmart materials and technologies empowered by nanotubesLearn moreOIL & GASGraphene nanotubes guarantee safety and productivityLearn moreFUTURE OF MOBILITYNanoaugmented transport – intelligent, functional and energy efficientLearn more

Application Cases for

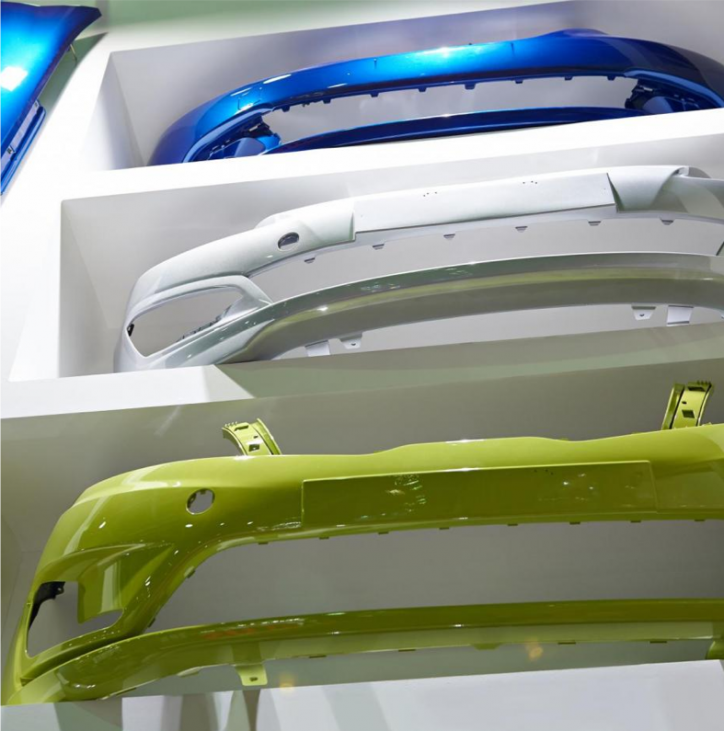

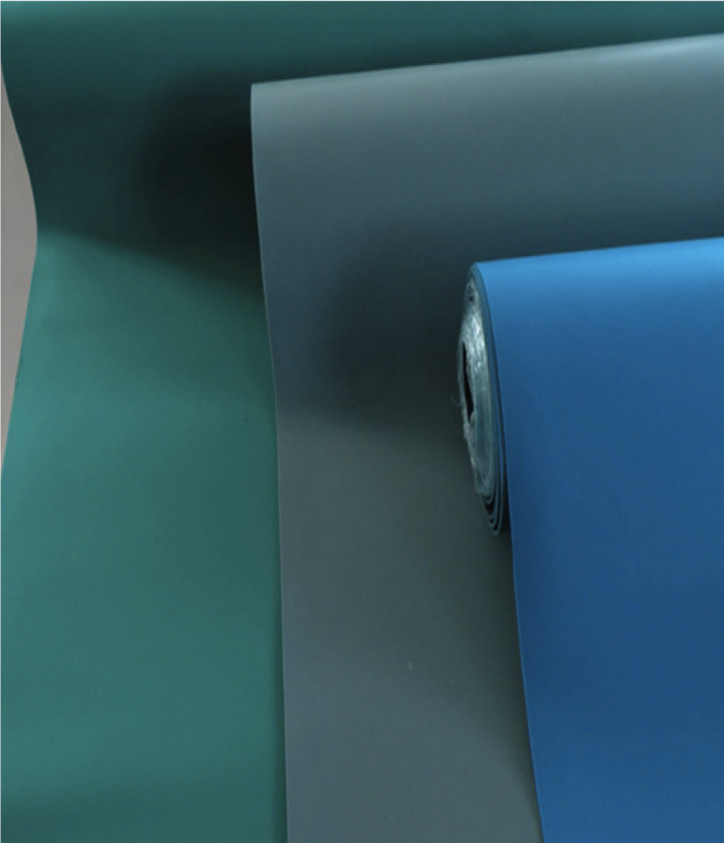

TUBALL™ for SMC COMPOSITES

Versatile conductive additive based on a plasticizer with a stabilizing agent for polyester and vinyl-ester coatings, for melamine and acrylic solvent-based applications

View Product

TUBALL™ for SMC COMPOSITES

PRODUCT

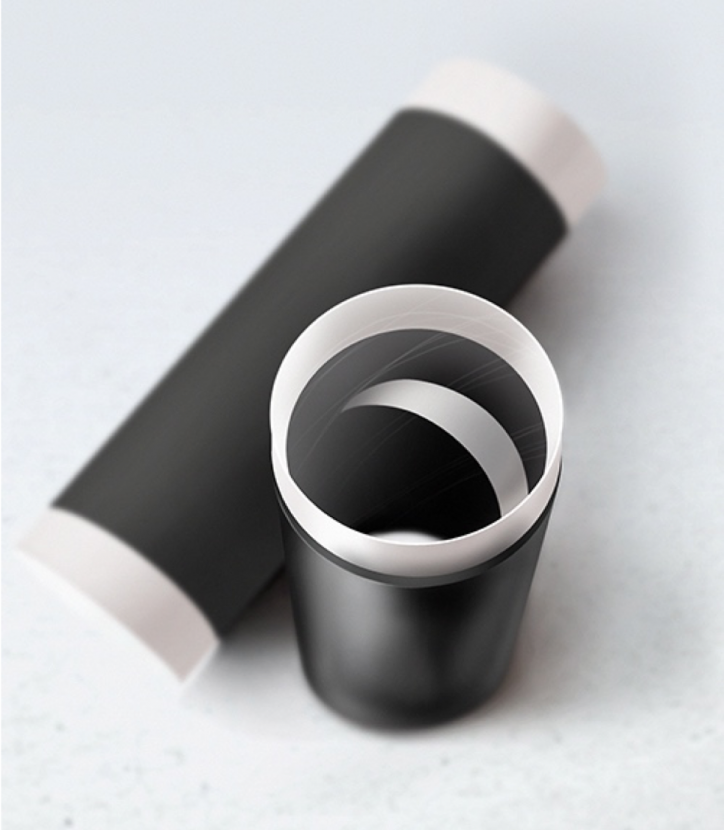

Anti-static SMC composites for using in electronic equipment

REQUIREMENTS

- Volume resistivity of 106–109 Ω∙cm

- Permanent and stable level of resistivity

TUBALL™ SOLUTION

6 wt.% of conductive carbon black as a conductive additive was replaced with

0.2 wt.% of TUBALL™ MATRIX 204

KEY BENEFITS

- Permanent and stable anti-static properties without “hot spots”

- Resistivity is independent of humidity

- Wide range of colors is available

- Clean manufacturing process without carbon black powder or dust

- Original flame retardancy is maintained

Product News

April 24

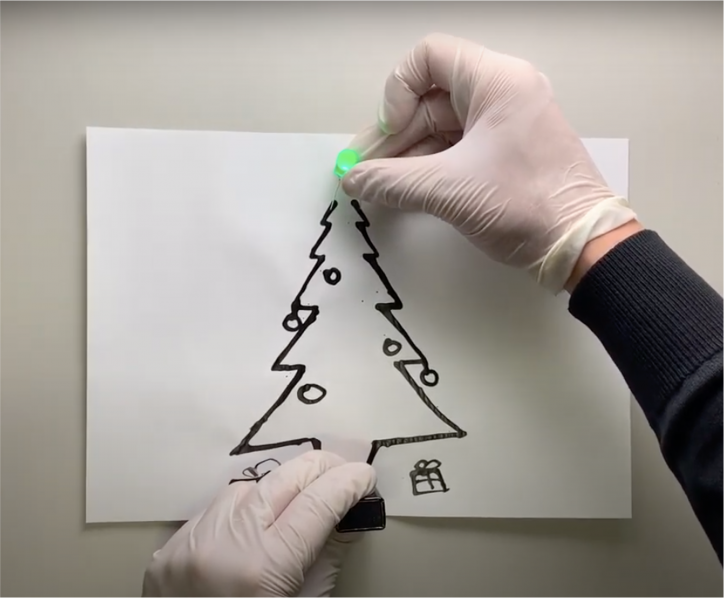

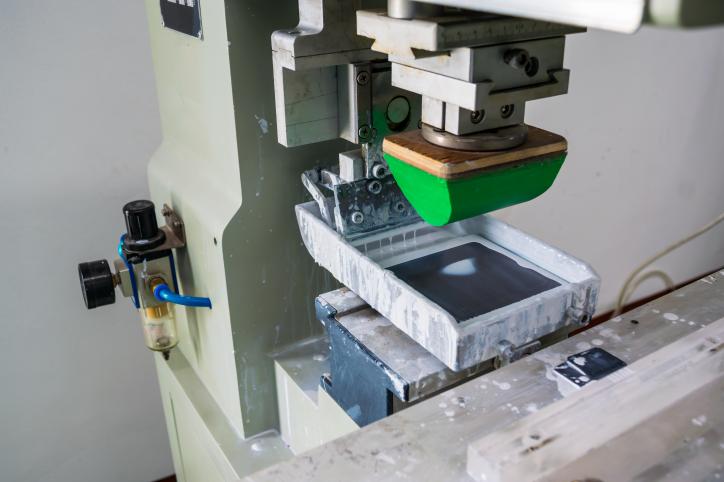

[#video] It’s hard to find another material as amazing as a graphene nanotube. Exceptional conductivity and mechanical strength, flexible with an ultralightweight structure and versatile functionality. They can’t be seen with the naked eye, but it’s easy to experience their power in materials they enhance!

Watch this 3-minute video: https://youtu.be/v5FkG2QYBWc

Learn more about TUBALL™ nanotubes: https://tuball.com/about-tuball?utm_source=Facebook&utm_medium=New+materials+revolution+teaser&utm_campaign=April+24%2724

#SWCNT #GrapheneNanotubes #nanotubes

Read on Facebook

April 23

[#MeetUs] 👋 Are you involved in advanced battery technology development? Join us in Chongqing at CIBF this week and discover the superior performance of high-solid-content dispersions with TUBALL™ nanotubes compared to alternatives in high-performance electrodes, thick cathodes, silicon anodes, and solid-state batteries. Dive into the world of nanotechnologies to empower your battery cells! 🚀

Learn more on nanotubes for batteries: https://tuball.com/nanotubes-in/li-ion-batteries?utm_source=Facebook&utm_medium=CIBF+announcement&utm_campaign=April+23%2724

#batteries #energy #CIBF

Read on FacebookHead office

1 Rue de la Poudrerie,

L-3364, Leudelange,

Grand-Duché de Luxembourg